End station A (ESA) SLAC National Accelerator Lab, participating in preparing the experiment to receive the electron beam, and monitoring the quality of the radiation exposure during the process.

Paul Anderson (paul@electronicautomations.com)

Senior Engineer at Pleno Inc.

Previous roles: Instrument Engineer at Roswell Biotechnologies. R&D Engineer at Bionaut Labs. Sr. Engineer at Pleno Inc. Currently, Sr. Dev Engineer at Oxford Instruments X-Ray Technology

Education: MS in Physics California State University Long Beach, BS in Physics University of California Santa Cruz

Awards, Fellowships, Papers, and Proceedings

Outstanding Initiative and Achievement, (Zenith Specialty Bag Co., Inc.)

Richard D Green Dean Graduate Research Fellowship, (CSULB)

“Updated Results of Solid-State Sensor Irradiation Study for ILC Extreme Forward Calorimetry”, https://arxiv.org/abs/1703.05429

“Strain-tuning of domain walls in multilayer graphene probed in the quantum Hall regime” https://journals.aps.org/prb/abstract/10.1103/PhysRevB.105.L081408

Thank you for visiting my page! Please scroll down to find information supplemental to my resume. Scroll to bottom of page for latest industry and freelance work examples.

Masters of Science in Physics program work

Graphene under strain using MEMS

Probing the effects of graphene under strain using micro-electrical-mechanical systems. Devices fabricated by Qin Zhou, Yifan Huang, UNL.

Master Thesis

Probing The Effects of Graphene Under Strain Using a Microelectromechanical Systems Device

Miniature Lock-in Amplifier prototype

Building and testing of a prototype lock-in amplifier.

Automated breakout box concepts

A conceptual design of a relay powered measurement breakout box, including AutoCAD schematics and Eagle/SPICE simulations.

Bachelors of Science in Physics program work

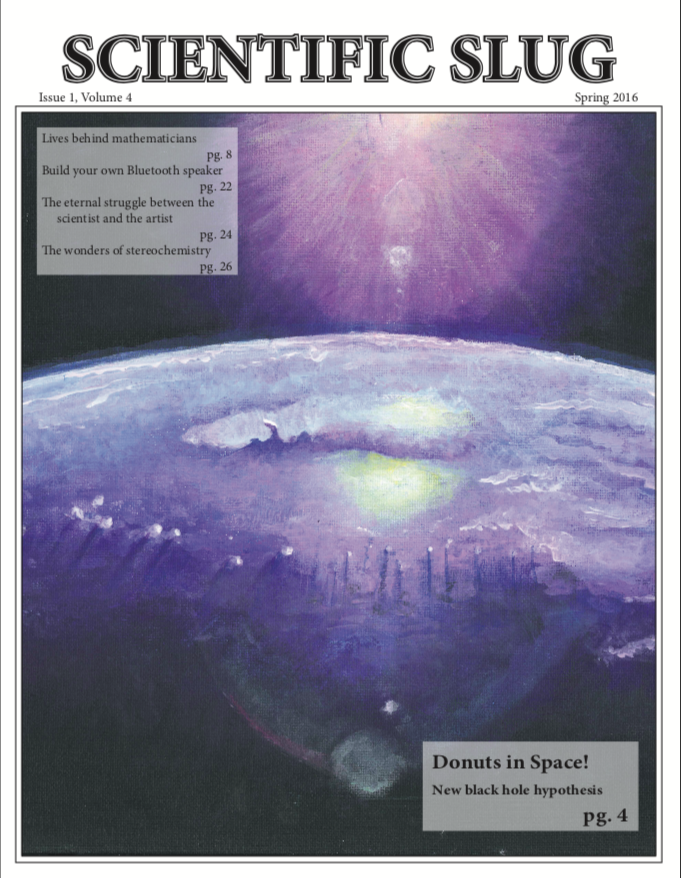

Scientific Slug Magazine, 2017

Scientific Slug is a student run magazine that aims to unite the artistic and scientific community at UCSC. As a writer and illustrator of the magazine, I would interview campus scientists and communicate their research to the community using a writing style geared toward the general audience supplemented by schematics and artwork.

Senior Thesis

"Development of Pulse simulations to Understand the Dependence of Collection Time on Shaping Time and Explore Solutions to the Trapping Mechanism."

Pre-Academia industry work

Automated Packaging Machine Prototype

A prototype I developed to automate the packaging of paper bags.

Three Web System

A bag forming unit I reverse engineered with added improvements of my own design. Image is a 3D AutoCAD model I produced.

Other projects:

High-current pulse magnetizer

Part of my freelance work includes the development of a high-current pulsing magnet charger, otherwise know as a magnetizer. Traditionally, this type of instrument would be used to magnetize materials using a coil fixture. Here, the application is much different but the principals of the machine as similar.

120V is input to a 120/230 step-up transformer, or if the source is 230V, an isolation transformer is used. The source is converted to DC by means of a rectifier and used to charge a large capacitor bank to 300V. A thyristor is used to switch the capacitor bank on and off. The thyristor method is used for currents less than 2kA. In the case that currents are large (up to 20kA), a thyristor is not sufficient and instead an ignitron is used to switch on the capacitor bank. Here, a thyristor and single capacitor can be used to ignite the mercury in the ignitron tube.

Magnetizer breadboard

Magnetizer capacitor bank (600V, 120mF)

Finished magnetizer instrument in 19” rack mount configuration

A bigger custom built magnetizer using ignitron switch. 700V charges 200mF capacitor bank.

A happy and complete magnetizer being shipped home.

Breakout box: from concept prototype to functioning instrument

The “automated breakout box concepts” as found in the page above was a proof of concept I developed in my MS program to propose an automated switchboard for performing experiments. This work paved the way for a recent project I’ve taken on at Roswell Biotechnologies. Here I have successfully developed a working automated breakout box instrument. The implementation of such a board has freed up dozens, if not hundreds of hours in experiment monitoring and operation of electrode switching.

Breakout board PCB design modeled in KiCAD

Breakout board in metallic box

My home laboratory in response to COVID 19

During the California shut down due to COVID-19, I was able to continue a portion of my work study molecular electronics by moving my lab setup to my home. Here I perform lock-in impedance measurements to study the electronic properties of biological molecules. I’ve simulated the electronic properties of “nano-wires” which can be modeled as unique molecules by generating a tight-binding Hamiltonian and literature based onsite energies and hopping terms. I model the IV and dI/dV (differential conductance) using Kwant in Python.

An differential conductance simulation using Kwant package in Python. Here I can model the electronic properties of a nano-wire. I test a hypothesis based on this type of simulation with the experimental setup shown to the left.

Designing a low temperature measurement probe

Low temperature measurement probe within vacuum sleeve

Measurement probe sample space: heat sinks, PLCC socket, magnet coil

Thermal analysis where flange is set to 293K and heat sinks to 10K

Here I have designed a liquid cryostat vacuum probe using AutoCAD Design Suite to generate a model, and AutoDesk Fusion 360 to perform a thermal analysis simulation.

Routine maintenance and repairs of closed cycle cryostat

A significant part of my work in the CSULB Nanoelectronics lab consisted of routine maintenance and repairs of lab equipment. Here I have learned much about the inner workings of a closed cycle cryostat. I have also been trained to pump and evacuate vacuum lines, replace and clean filters, replace scroll pump tip seals, pump and flush and recharge the UHP (ultra high purity) helium circulation system. Since my experiments depend on the functionality of this system, I take special care while learning about and maintaining this system. In addition to this Oxford Instruments Teslatron, I have also done experiments in and repairs on a Quantum Design PPMS (physics properties measurement system).